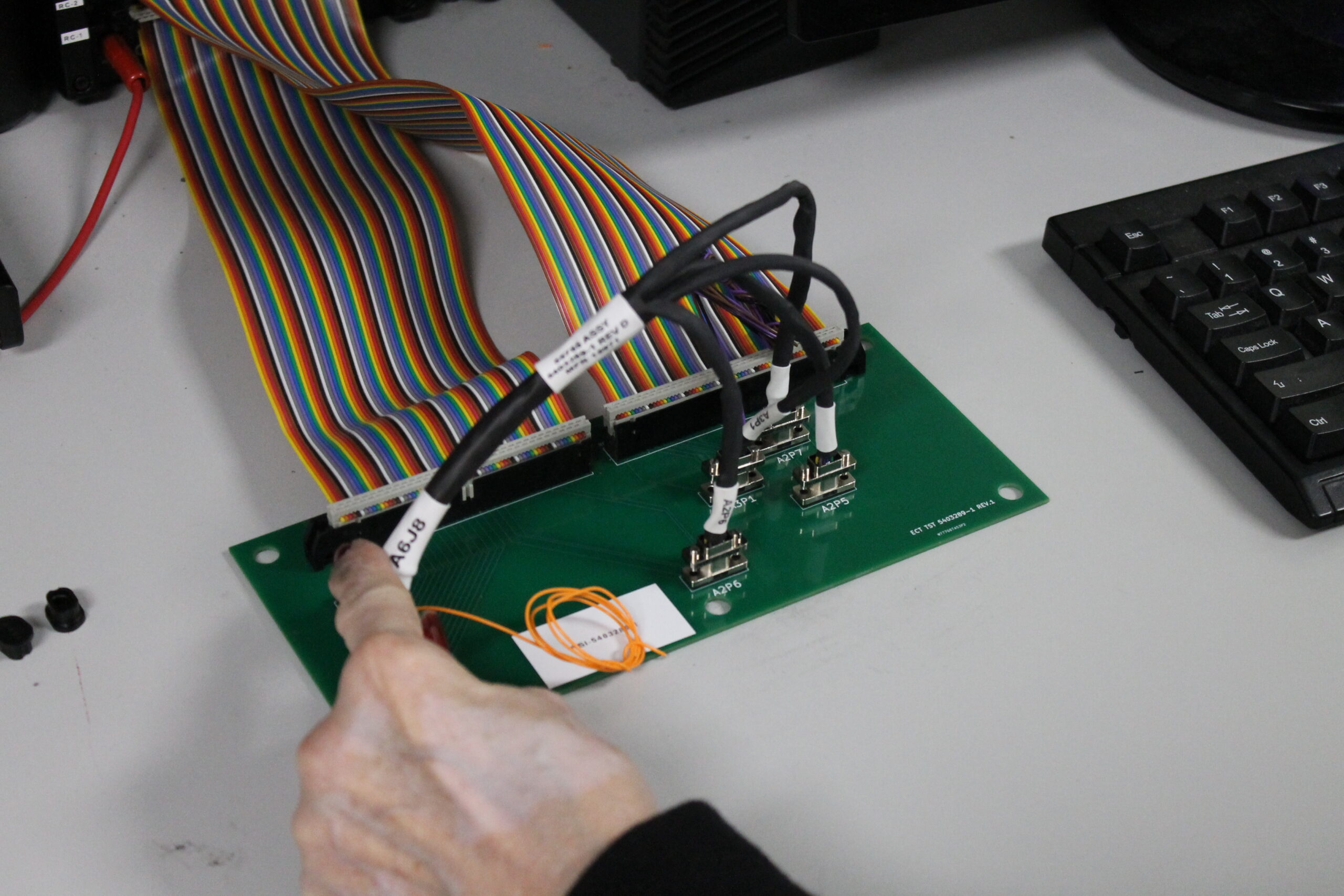

At ECI Cables, quality isn’t an afterthought, it’s our foundation. Every project begins with a thorough inspection of incoming materials before they ever enter production. From there, each component is carefully handled, checked, and rechecked through every stage of the assembly process.

Before a single product leaves our facility, it undergoes rigorous final inspections and performance testing to ensure it meets your exact specifications and industry standards.

Our commitment to excellence starts with our team. Every ECI employee receives in-depth training to expertly carry out their role in cable and harness manufacturing. We proudly build to WHMA-620-A standards, the industry benchmark for wire harness quality and employ a certified instructor on staff to ensure ongoing education and compliance.

STANDARDS

EQUIPMENT

Quality Policy/Mission Statement:

ECI Cables is committed to meeting our customer’s requirements through continuous improvement of our quality management system, focusing on customer satisfaction and delivering a superior quality product in a timely manner.